If you’ve ever watched a packaging line turn out rolls of beautifully printed film or paper and wondered how such consistent precision is achieved, the secret often lies in the stack flexo printing machine—a compact yet powerful system designed to deliver vibrant, multi-color prints with speed and control. In this article, PuJi Packaging Machinery walks you through the working process of a stack flexo printing machine, exploring each stage in detail and explaining why it continues to be a preferred choice for packaging manufacturers worldwide.

Table of Contents

ToggleKey Components of a Stack Flexo Printing Machine

Understanding the anatomy of your machine is essential before diving into how it operates; after all, every flawless print is the result of several components working in seamless coordination.

Print Stations – Vertical Stacking for Multi-Color Prints

The hallmark of the stack flexo design lies in its vertically arranged print stations, each responsible for a single color, which together build complex multi-color images layer by layer; this configuration saves floor space while allowing easy access to each color deck for maintenance and setup. Each station houses its own inking, plate, and impression system, providing precise color control and quick changeovers.

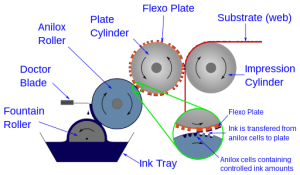

Anilox Rollers – Control Ink Transfer Precisely

At the core of flexographic printing is the anilox roller, a carefully engraved cylinder that meters the ink and transfers it consistently to the plate cylinder; with its tiny, laser-etched cells, it ensures uniform ink coverage, eliminating excessive ink flow and reducing the chance of dirty prints or color inconsistency. High-quality ceramic-coated anilox rollers, as recommended by PuJi Packaging Machinery, extend lifespan and guarantee sharper output.

Plate Cylinders – Transfer Images onto the Substrate

The plate cylinder holds the flexible photopolymer plate carrying your printed image, and it is here that your design comes to life; the raised image areas receive ink from the anilox roller and then transfer it directly to the moving substrate. Precision alignment between cylinders is critical—slight misalignments can lead to ghosting or blurry text, issues that PuJi’s machines counter through advanced registration systems.

Impression Rolls – Ensure Consistent Contact and Print Quality

Each color station includes an impression roll, which presses the substrate against the plate cylinder, ensuring consistent ink transfer and even pressure across the material. The accuracy of this contact is what defines clarity, tone, and overall print quality; a well-calibrated impression roll eliminates streaks and uneven color layers.

Drying Systems – UV or Hot-Air Dryers for Quick Curing

After each color layer is applied, it must be dried or cured before the next one is printed. Drying systems, typically hot-air or UV-based, are integrated between color decks to speed up production while preventing ink smudging. Modern systems—like those featured in PuJi’s models—offer energy-efficient drying, maintaining speed without sacrificing color density.

Web Handling System – Tension Control for Smooth Substrate Movement

A web handling system is the unsung hero that keeps the substrate (whether paper, film, or foil) perfectly aligned and tensioned throughout the printing process; precise tension control prevents wrinkles, stretching, or misregistration, ensuring every color layer lands exactly where it should.

Step-by-Step Working Process

Now that you understand the anatomy, let’s walk through how the stack flexo printing machine performs its magic—from feeding to final rewinding.

Substrate Feeding

The process begins with rolls of raw material—film, paper, or foil—being unwound and guided into the machine through the web handling system. Smooth and accurate feeding is vital; inconsistent feed tension can ruin even the best print job, causing color shifts or stretching.

Ink Application

Next, ink from the ink fountain is transferred to the anilox roller, which carefully meters the exact amount needed. The anilox roller then delivers this ink to the plate cylinder, coating only the raised areas of the image. This precise metering ensures consistent ink density, which in turn results in crisp, high-quality prints.

Printing

Here’s where the actual printing occurs: as the substrate passes between the plate cylinder and the impression roll, the inked image is transferred directly onto the substrate surface. Each vertically stacked station prints one color—cyan, magenta, yellow, black, or spot colors—and the substrate moves upward through each level until the final image is complete.

Drying / Curing

Between each print station, the inked surface enters a drying or curing system, which solidifies the ink before the next layer is applied. UV dryers instantly cure UV-sensitive inks, while hot-air systems evaporate solvents or water from the ink. Efficient drying maintains color vibrancy and prevents smudging, especially at high printing speeds.

Registration & Alignment

As the substrate travels through multiple color decks, precise registration is essential. The machine’s registration system continuously monitors the position of each printed image, making micro-adjustments in real time. PuJi’s intelligent registration control ensures colors remain perfectly aligned, even at high-speed runs of up to 300 m/min.

Finished Product Output

Finally, the fully printed and dried substrate is rewound into rolls or directed toward downstream finishing equipment like laminators, slitters, or die cutters. The result is a flawless, multi-colored product—ready for packaging or further processing.

【Summary Table – Working Stages of Stack Flexo Printing】

| Stage | Main Component | Function | Key Control Parameter | Potential Issue | Solution |

|---|---|---|---|---|---|

| Feeding | Web Handling System | Guides and maintains tension of the substrate | Tension Control | Wrinkles or web drift | Auto-tension adjustment |

| Ink Application | Anilox Roller | Transfers a controlled amount of ink to the printing plate | Ink Viscosity | Ink overflow | Regular cleaning |

| Printing | Plate Cylinder | Transfers the printed image onto the substrate | Pressure Balance | Blurry image | Recalibrate pressure |

| Drying | UV/Hot-Air System | Solidifies or cures the ink layer | Temperature | Smudging or incomplete curing | Adjust dryer settings |

| Rewinding | Output Roll | Collects the finished print | Speed Synchronization | Misalignment or uneven winding | Automated control system |

Advantages of Stack Flexo Printing Machines

Operating a stack flexo printing machine offers numerous benefits that go far beyond aesthetics; its engineering is designed for speed, flexibility, and reliability in industrial environments.

Efficient multi-color printing in a compact footprint

The vertical stack configuration minimizes floor space while maximizing color versatility—an ideal setup for manufacturers juggling multiple product lines.

High-speed production for large-volume jobs

With quick drying and automatic tension control, these machines handle long runs effortlessly, keeping productivity high even on demanding shifts.

Suitable for diverse substrates (paper, film, foil)

Whether you’re printing on delicate film or thick kraft paper, flexo’s adaptability ensures quality across all materials—making it perfect for flexible packaging.

Reduced waste and improved color consistency

Advanced inking and registration systems minimize waste while maintaining perfect color balance from the first print to the last, boosting efficiency and sustainability.

FAQs

What types of materials can a stack flexo printing machine handle?

It can print on paper, film, foil, and other flexible substrates—basically anything that can move smoothly through a web press.

How many colors can be printed in one pass?

Most machines feature four to eight color stations, allowing for full CMYK and spot color combinations.

What’s the main advantage over a CI flexo press?

Stack flexo machines are more compact and cost-efficient, making them ideal for medium-scale operations needing multi-color flexibility.

Does it require special inks?

Not necessarily; both solvent-based and water-based inks work well, but matching the ink to your substrate ensures the best results.

Is maintenance difficult?

Routine cleaning and calibration are key, but PuJi machines are designed for easy access and quick component swaps, minimizing downtime.

Conclusion

When you understand the working process of a stack flexo printing machine, you realize it’s not merely a printing press—it’s a perfectly synchronized ecosystem where engineering, ink chemistry, and digital control converge. Every stage, from ink metering to drying, plays a crucial role in achieving sharp, vivid, and repeatable results. Whether you’re producing flexible packaging for snacks, cosmetics, or industrial applications, choosing a reliable system like those from PuJi Packaging Machinery ensures not just performance but peace of mind.Ready to streamline your production line and deliver premium-quality prints with every run? Get in touch with PuJi today and explore how our stack flexo solutions can transform your packaging operations.