In the fast-evolving world of flexographic printing, achieving unparalleled speed, precision, and reliability is paramount for brands and converters aiming to stay competitive. One technological advancement that has fundamentally transformed modern Central Impression (CI) flexo presses is the integration of gearless drive systems. Unlike traditional geared mechanisms, gearless technology utilizes independent, servo-driven motors for each print unit, offering unprecedented control and flexibility. This innovation is particularly critical for high-speed operations in industries like packaging, where consistency and efficiency directly impact profitability. At PuJi Machinery, we are at the forefront of this revolution, engineering advanced, gearless CI flexo presses that deliver superior performance, reduce operational costs, and meet the demanding needs of today’s high-volume print environments. For businesses seeking to enhance their packaging printing efficiency and print registration accuracy, understanding the role of gearless technology is the first step toward future-proofing your operations.

Table of Contents

ToggleWhat is Gearless Technology in CI Flexo Presses?

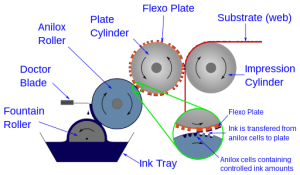

Gearless technology replaces the traditional mechanical gear-driven system with individual servo motors for each printing unit and the central impression cylinder. This configuration allows for completely independent, digitally precise control of the print cylinder’s rotation and positioning. By eliminating physical gears, the system removes a primary source of mechanical backlash, vibration, and wear. This results in a direct-drive mechanism that enhances responsiveness and enables finer adjustments during high-speed operation, which is essential for maintaining perfect registration and consistent print quality across long runs.

Key Benefits of Gearless Drive Systems

The adoption of gearless technology brings a host of operational and qualitative advantages that address long-standing challenges in flexo printing.

Enhanced Print Quality and Registration Accuracy

Without the mechanical play inherent in geared systems, gearless presses achieve near-perfect registration stability. Each servo motor can make micro-adjustments in real-time, compensating for substrate stretch or environmental factors. This leads to sharper graphics, consistent color laydown, and the ability to print intricate details and fine text—a crucial factor for high-end packaging and labels.

Increased Operational Speed and Productivity

Gearless drives enable faster ramp-up to operational speeds and more dynamic speed control during printing. The reduction in mechanical vibration and inertia allows presses to run smoothly at higher velocities without sacrificing quality. This translates directly to higher throughput and shorter production times for time-sensitive jobs.

Reduced Maintenance and Higher Reliability

Traditional gears require regular lubrication, are prone to wear, and can suffer from tooth fatigue. A gearless system significantly reduces the number of wearing mechanical parts, minimizing scheduled maintenance and unplanned downtime. The robust design of servo motors leads to a longer operational lifespan and greater overall press reliability.

Greater Flexibility and Job Changeover Efficiency

Gearless technology simplifies job changeovers. Preset job recipes can automatically adjust cylinder circumferences and positions digitally, without manual gear changes. This slashes makeready times, reduces waste during setup, and allows for more efficient handling of short to medium runs alongside long production jobs.

Energy Efficiency and Sustainability

Independent servo motors consume power only when and where needed, unlike a central gear drive that runs constantly. This targeted energy use, combined with reduced waste from setup and misregistration, lowers the overall carbon footprint of the printing process, aligning with modern sustainability goals.

Gearless vs. Traditional Geared CI Flexo Presses

| Feature | Gearless CI Flexo Press | Traditional Geared CI Flexo Press |

|---|---|---|

| Registration Control | Digital, independent servo control for micro-adjustments. | Mechanical, limited by gear backlash and wear. |

| Maximum Operational Speed | Higher potential speeds with stable quality. | Speed limited by mechanical vibration and inertia. |

| Maintenance Requirements | Low; primarily focused on servo motors and bearings. | High; regular gear lubrication, alignment, and replacement. |

| Changeover Time | Fast; digital job presets and automatic positioning. | Slow; manual gear changes and mechanical adjustments. |

| Print Quality Consistency | Excellent over long runs; minimal vibration impact. | Can degrade due to gear wear and mechanical play. |

| Initial Investment | Higher due to advanced drive technology. | Lower initial capital cost. |

| Long-Term Operational Cost | Lower due to energy savings, less waste, and reduced downtime. | Higher due to maintenance, waste, and potential downtime. |

Registration Control: The digital servo control in gearless systems allows for automatic, real-time compensation. For instance, if a sensor detects substrate tension variation, the system can instantly adjust the rotation of a single print cylinder to maintain perfect dot-on-dot registration. In geared presses, this level of correction is mechanically impossible, often requiring a press stop for manual adjustment, leading to waste and downtime.

Maintenance Requirements: A traditional geared press demands a rigorous maintenance schedule involving gear oil changes, wear inspection, and alignment checks. Gear teeth are subject to pitting and scoring, which directly degrades print quality. In contrast, a gearless press eliminates these concerns. Maintenance shifts to predictive monitoring of servo motor performance and periodic bearing checks, resulting in lower lifetime cost of ownership and less production disruption.

Changeover Time and Flexibility: Changing a print repeat length on a geared press involves physically changing gear sets—a time-consuming and labor-intensive process that requires technical expertise. A gearless press redefines this process. The operator simply inputs the new repeat length into the control interface. The servo motors automatically reposition and synchronize to the new circumference. This not only reduces changeover from hours to minutes but also minimizes human error and material waste during setup, enhancing overall equipment effectiveness (OEE).

Why Gearless Technology is the Future for High-Speed Printing

For converters targeting markets like flexible packaging, labels, and corrugated pre-print, the demands for speed, versatility, and quality have never been higher. Gearless technology is not merely an incremental improvement; it represents a paradigm shift. It enables the agility needed for just-in-time production models, supports the high-resolution graphics demanded by brands, and provides the reliability required for continuous, unattended operation. Investing in a gearless CI press is an investment in capability, resilience, and long-term competitiveness.

PuJi Machinery’s Commitment to Advanced Gearless Solutions

At PuJi Machinery, we integrate cutting-edge gearless servo technology into our high-speed CI flexo press designs. Our systems feature user-friendly digital interfaces, robust servo drive components from industry leaders, and comprehensive technical support. We ensure our clients can fully leverage the benefits of gearless operation—from reduced waste and energy consumption to achieving superior print quality that wins in the marketplace.

FAQ

Q: Is gearless technology only beneficial for very high-speed presses?

A: No. While it excels at high speeds, its advantages in registration accuracy, quick changeovers, and reduced maintenance are valuable for presses operating at any speed, improving efficiency and ROI across diverse job portfolios.

Q: Are gearless presses more difficult for operators to learn?

A: Not at all. The digital control systems are often more intuitive, with automated setups and troubleshooting guides. Training focuses on software operation rather than complex mechanical adjustments, which can shorten the operator learning curve.

Q: How does gearless technology impact the ability to print on delicate or stretchy films?

A: It significantly improves it. The independent servo control allows for precise tension and registration management, adapting in real-time to substrate behavior. This reduces waste and improves quality on challenging materials like thin PE films.

Q: What is the typical lifespan of the servo motors in a gearless system?

A: Servo motors are designed for industrial durability and can last for decades with proper care. Their lifespan often exceeds that of the mechanical components they replace, and they are typically modular for easy servicing or replacement if needed.

Q: Can existing geared presses be upgraded to gearless technology?

A: A full retrofit is generally not feasible due to fundamental design differences. The investment in a new gearless press is recommended to gain the complete system benefits in performance, integration, and long-term support.

Conclusion

Gearless technology is redefining the benchmarks for modern high-speed CI flexo presses. By delivering unmatched registration accuracy, faster job changeovers, lower maintenance, and superior operational efficiency, it provides a clear pathway to greater productivity and profitability. For any converter serious about leading in the digital age, adopting gearless drive systems is a decisive step forward.

Ready to experience the next generation of flexo printing performance? Discover how PuJi Machinery‘s gearless CI flexo presses can transform your production capabilities. Visit Our Web to explore our innovative solutions and speak with our experts today.