In today’s fast-paced manufacturing world, efficiency, precision, and adaptability are key. That’s where slitting machines—also known as slitter machines—come into play. If you’ve ever wondered “what is a slitting machine”, this guide will walk you through everything you need to know: from its components and types to how it’s used across various industries.

Whether you’re in packaging, automotive, textiles, or electronics, understanding the role of slitting equipment can help you optimize your production process, reduce waste, and increase output quality.

Table of Contents

Toggle1.What is a Slitting Machine?

A slitting machine is an industrial device used to convert large rolls of material—known as master rolls—into narrower, more manageable strips. This process, called slitting, involves unwinding the material, cutting it precisely using blades, and rewinding it into new rolls.

These machines are designed to handle various materials, including:

- Plastic films

- Paper

- Aluminum foil

- Laminates

- Textiles

- Nonwoven fabrics

A slitter machine offers manufacturers a fast and accurate method for customizing material widths to suit specific production needs

2.Key Components of a Slitting Machine

A typical slitting machine consists of several core components that ensure precision and efficiency:

- Unwinding Unit: Holds and feeds the master roll into the machine.

- Slitting Section: Equipped with rotary blades, razor blades, or score knives depending on the application.

- Rewinding Unit:Collects the slit material into new, narrower rolls (also called “slit rolls” or “rewind rolls”).

3.Types of Slitting Machines

3.1Rotary Slitting Machine

- Uses circular blades rotating against each other.

- Ideal for high-speed operations.

- Commonly used for paper, foil, and film.

3.2Razor Slitting Machine

- Utilizes razor-sharp blades for thin, flexible materials.

- Best for plastic films and light laminates.

- Offers excellent precision but slower speeds.

3.3Score Slitting Machine

- Involves pressing a circular blade against a hard roller.

- Suitable for thicker materials like paperboard or fiberboard.

- Less precise but robust for heavy-duty tasks.

4.Applications of Slitting Machines

Slitting machines are used in a wide range of industries due to their adaptability and precision. Common applications include:

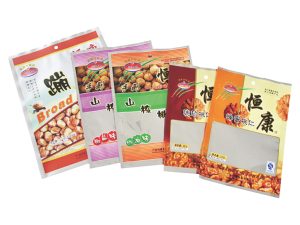

- Packagingindustry: Slitting laminated films for flexible packaging.

- Textiles and Non-wovens: Custom-width fabric rolls for fashion and medical use.

- Automotive:Process metallic and plastic laminates into automotive trim and insulation strips.

- Electronics:Cut ultra-thin films and foils with micron-level precision.

- Label Production:Core-equipped slitters generate rolls for label converting.

- Printing: Slit master rolls of paper or film for printing presses, tickets, or receipts.

Wrapping Up

So, what is a slitting machine? In essence, it’s a vital piece of industrial machinery that transforms large material rolls into precise, usable widths—saving time, reducing waste, and maximizing productivity. With applications across nearly every industry, investing in the right slitter machine or slitting equipment is essential for any business looking to scale efficiently.

Curious about customized slitting solutions? Reach out for a consultation and discover how our slitting machines can transform your production—boosting speed, precision, and ROI.