With years of industry expertise and an innovative mindset, we’ve consistently pushed boundaries, earning the trust and support of numerous clients.

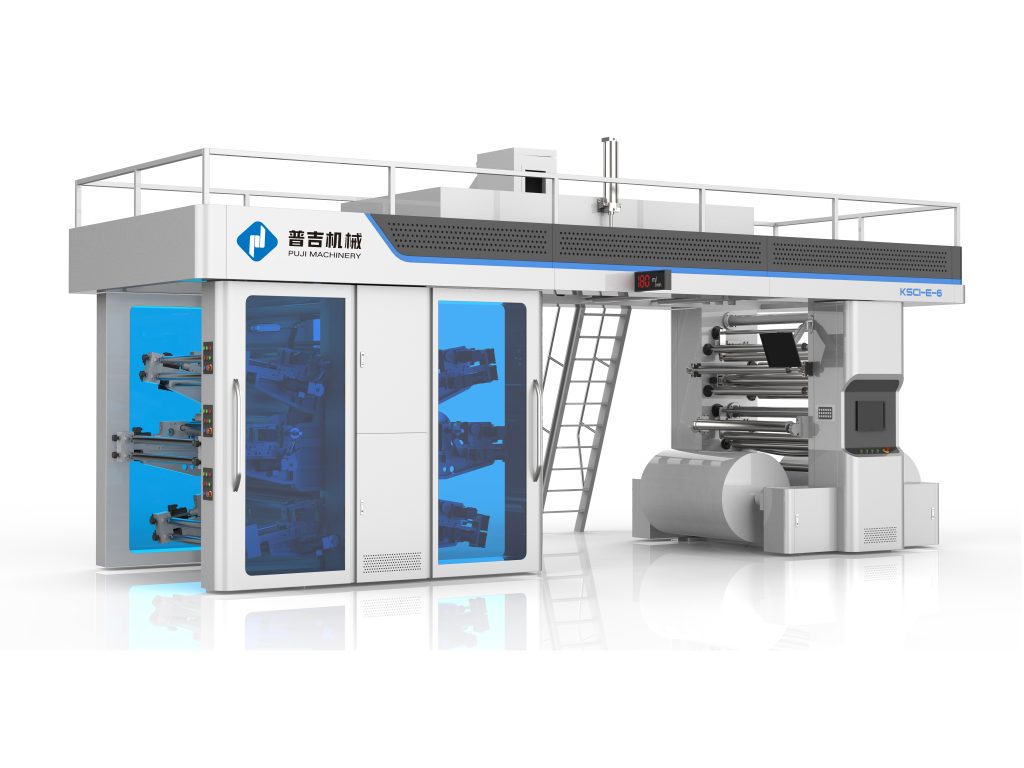

The Flexo Printing Machine Series is designed to meet the evolving demands of the modern packaging industry. It includes a range of models such as gearless flexo presses and CI (central impression) flexo machines, offering high-speed, high-precision printing on various materials like paper, plastic film, and foil. With advanced tension control, servo drive systems, and accurate color registration, these machines ensure excellent print consistency even during long production runs.

In addition to superior printing performance, this series emphasizes energy efficiency, user-friendly operation, and easy maintenance. Its modular design allows for flexible customization based on specific production needs, making it suitable for applications in food packaging, labels, flexible packaging, and more. Whether you’re handling small batch jobs or large-scale production, the Flexo Printing Machine Series delivers stable, reliable, and cost-effective printing solutions.

We offer customized machine services where customers can download and fill out a requirement sheet based on the bag-making solution and send it to us for quotation and further details. For logistics and installation, we provide a preparation checklist before machine setup, arrange for our engineer to offer overseas installation services, and train workers on machine operation, ensuring the entire process is followed up until completion. After usage, we establish a tripartite feedback group, send a questionnaire after 15 days of operation, and collect feedback including photos of finished bags, the machine in use, and the customer’s team to help us continuously improve our service and support.

1. Download custom requirementsheet,check on bag making solu-tion for reference.

2. Fill in the requiement.

3. Send to us and contact us for quotation and details.

1.Send you the list should prepare.

2.Prepare the necessity before machine installation.

3. Arrange engineer overseas ser-vice to instal the machine andtraining the workers how to operate the machine.

4. Follow up the installation until itis finished.

1. Setup the tripartite group.

2. Send questionare after 15 daysof use.

3. Feedback the prictue fo your bag,machine with your stronger team.

Our flexographic printing machine is widely used in the non-woven fabric, roll paper, and plastic film industries. It is designed to deliver high-quality prints on a variety of flexible materials, offering precision and versatility for different packaging needs.

A: We are a factory manufacturing packaging&printing machines and we provide perfect OEM and after-sale service. We export machines to over 108 countries since 1995.

A: We are a factory manufacturing packaging&printing machines and we provide perfect OEM and after-sale service. We export machines to over 108 countries since 1995.

A: We are a factory manufacturing packaging&printing machines and we provide perfect OEM and after-sale service. We export machines to over 108 countries since 1995.

Yes, we provide manuals, operation videos, and 3D drawings. We can also create test videos using materials from your packaging goods, if available locally.

We are a manufacturer with our own factory. We also have a global service team offering excellent after-sales support.

We are located in Wenzhou, Zhejiang Province, China. Our location is easily accessible by air or train, and we can arrange to pick you up at the station.

Yes, we can send engineers to install the machine and train your staff. Alternatively, we can provide detailed video instructions to help reduce your costs.

You can review our business license and certifications. For additional security, we offer Letters of Credit to guarantee payment safety, timely delivery, and machine quality.