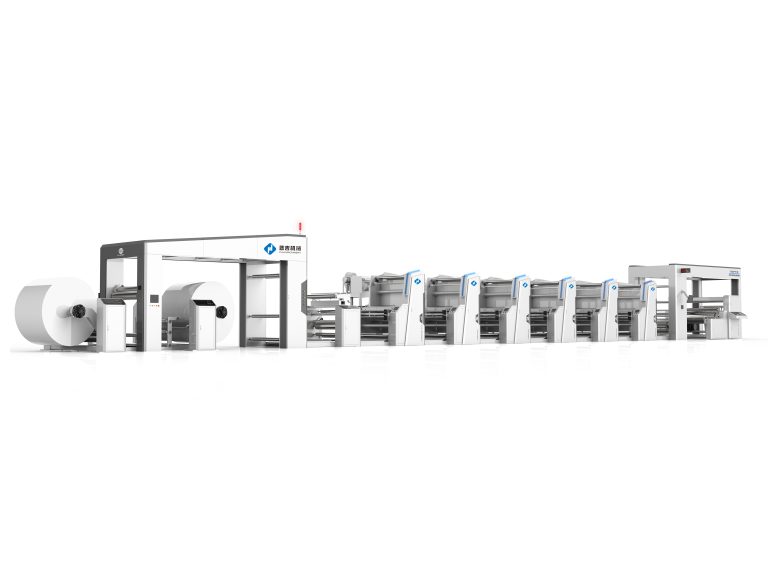

Printing material:

Paper cups, paper bags, carton pre-printing, food packaging, tobacco and alcohol outer packaging, drug packaging, daily necessities, non-woven fabrics, plastic films, industrial products, and other flexible packaging materials.

1.The whole machine is controlled by PC and servo motor control system; And equipped with remote service device to facilitate and quickly solve problems

2.The color registration adopts automatic computer automatic color registration and HD color still picture monitoring, which is convenient for the observation of printing quality

3.Unwinding adopts shaftless hydraulic automatic feeding, which is suitable for 3 + 6 inch paper core

4.The high-performance deviation correction system is adopted for discharging and deviation correction to ensure the linear stability of the substrate operation process and the end face uniformity of the winding finished product

5.High precision ceramic anilox roller, fully enclosed chamber doctor blade and pneumatic automatic ink pumping system are used for inking

6.Applicable ink: water-based ink, solvent ink and UV ink

7.The printing pressure is adjusted by electric control, which is convenient and fast for color registration

8.Plate cylinder adopts sleeve type, which is convenient for rapid plate changing

9.High precision tension sensor, multi-stage tension control; Floating roller detection to ensure accurate and stable printing tension

10.Independent extended oven, electric heating and drying unit, high efficiency and energy saving. Heat transfer oil or steam heating mode can also be selected

11.The material rewinding is controlled by servo motor and hydraulic automatic blanking

Main Technical Parameters

| Model | PJUH-TS-B-650-1650mm |

| Raw material width | 600-1600mm |

| Maximum printing width | 570-1570mm |

| Printing color | 2-10color |

| Printing length range | 360mm-960mm |

| Raw material diameter | Ф1500mm |

| Maximum mechanical speed | 50-260m/min |

| Maximum printing speed | 50-230m/min |

| Printing precision | ± 0.12mm |

| Color registration mode | Fully automatic computer registration |

| Voltage | 3P-380V-50HZ |

| Size | depends on the model |

| Weight | depends on the model |

| Other optional | 1)Fully automatic non-stop unwind&rewind 2)Sleeve anilox roller device 3)Pressure regulation: servo motor control 4)Turning bar device 5)UV and bronzing device 6)Slitting, breaking device |