Suitable printing material:

Roll paper, Plastic film, Non-woven fabric, Woven bag, and so on (Roll style of packaging material)

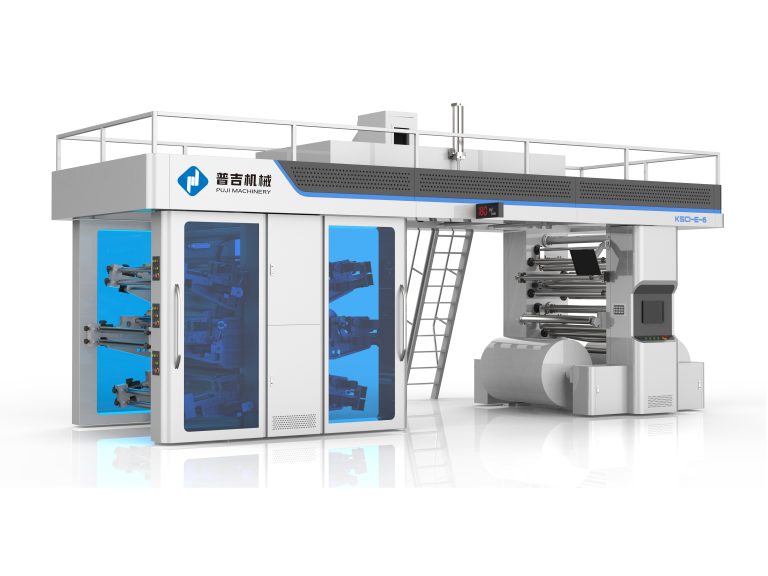

The main printing plate is flexible photosensitive resin plate or rubber, printed by anilox roller with ink. General process, unwinding unit, tension controller unit, traction feeding unit, printing unit, dryer unit, traction rewind unit and rewinding unit, all unit is controlled by PLC system. This machine has the advantages of reasonable structure, fast operation, simple operation, and it is the ideal flexible packaging equipment in China.

Specification

1.Single station or double station unwinding unit with 3” air shaft, edge position controller and tension controller, and warn for exchanging the unwinding, automatic stop the machine when the material is broken.

2.The main motor is controlled by frequency converter, the transmission adopt high precision synchronous belt or servo motor.

3.Unwinding style: Feeding paper by double rollers pressed, the pressure of unwinding is controller by pneumatic device. To ensure accuracy of register, the tension size is controlled by taper control technology.

4.Printing unit: Ceramic anilox roller with single doctor blade or enclosed doctor blade, automatic ink; anilox roller and plate roller is separated by hydraulic pressure when the machine was stopped. The anilox roller is driving by independent motor, to ensure the ink don’t freeze on the surface of anilox.

5.The pressure of rewinding is controller by pneumatic device: can add the static image detection system (Optional)

6.Single station or double station rewinding unit with 3” air shaft, rewinding by motor, and the machine will be stopped when the material is broken.

7.Independent dry system: IR heating (The temperature can be adjusted)

8.All system is controlled by PLC system, you can change by touch screen. It equip with automatic counting meter and changing speed.

Main Technical Parameters

| Model | BFYT-B-600-3200mm |

| Width of material | 600mm-3200mm |

| Printing width | 570-3170mm |

| Printing length | 280-1000mm |

| Printing color | 2-10colors |

| Diameter of roll material | Ф600 or Ф1200mm |

| Machine speed | 50-150m/min |

| Printing speed | 50-130m/min |

| Register precision | +-0.15mm |

| Weight(Kg) | It depends on the type |

| Dimension(m) | It depends on the type |

| Voltage | 3 Phase-380V-50HZ |

|

Optional unit | 1、UV dryer unit 2、Slitting device: Straight knife or circular knife 3、Corona treater unit 4. Electrostatic elimination or dust removal unit 5. Attachment device unit 6. Static image detection system unit |