Looking to elevate your labeling and packaging operations? Inline flexo printing machines provide unmatched precision, speed, and versatility. From food packaging inline flexo solutions to pharmaceutical labels inline printing, these machines can transform your production line, reduce costs, and enhance product appeal. 10 key benefits you should know that make inline flexo machine a must-have for modern packaging operations.

Table of Contents

Toggle1. Superior Print Quality for Labels and Packaging

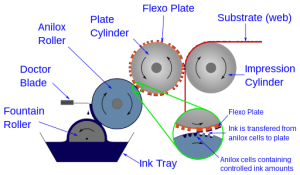

High-Precision Printing

Inline flexo printing delivers sharp, vibrant, and consistent images for all your labels and packaging. By integrating multiple print units into one machine, it ensures accurate color registration and reduces errors. You’ll achieve professional-grade prints that enhance your product appearance and brand reputation without the need for multiple quality checks.

2. Increased Production Efficiency

Streamlined Workflow

Inline flexo presses combine printing, varnishing, laminating, and die-cutting in a single continuous process. This integration cuts down setup and transition times, allowing you to produce more in less time. Faster throughput means you can meet tight deadlines and increase output without adding extra shifts or labor.

3. Cost Reduction and Waste Minimization

Save on Materials and Expenses

With precise registration and minimal setup errors, inline flexo printing reduces material waste and ink consumption. Lower waste directly translates to reduced operational costs, making it a smart choice for businesses looking to optimize their production budget.

4. Enhanced Flexibility for Multiple Substrates

Versatile Material Handling

Whether you work with paper, film, foil, or laminates, inline flexo presses accommodate a wide variety of substrates. Switching between materials is fast and efficient, so you can take on diverse projects without slowing down your production line.

5. Advanced Inline Varnishing and Coating Options

Add Premium Finishes in One Step

Many inline flexo machines feature integrated UV varnish, aqueous coatings, or specialty finishes. You can achieve matte, gloss, or tactile effects directly on the press, eliminating extra processing steps and delivering premium packaging that stands out on shelves.

6. Optimized Food Packaging Solutions

Safe and Compliant for Edible Products

Inline flexo printing is ideal for food packaging, offering precise registration for labels, nutritional information, and expiration dates. Using low-migration inks and compliant coatings ensures your packaging meets regulatory standards while maintaining high-quality visuals that attract consumers.

7. Accurate and Reliable Pharmaceutical Labels

Precision You Can Trust

Pharmaceutical labels demand accuracy for safety and compliance. Inline flexo presses deliver perfectly aligned barcodes, QR codes, and variable data every time. This reduces mistakes, ensures traceability, and protects your brand’s credibility in highly regulated markets.

8. Improved Automation and Reduced Labor Dependency

Work Smarter, Not Harder

Modern inline flexo presses include automated tension control, registration systems, and remote monitoring. Less manual intervention means fewer errors, lower labor costs, and smoother production workflows, allowing you to focus on other areas of your business.

9. Customization and Personalization Capabilities

Tailored Printing for Every Product

Inline flexo printing supports variable data and customization. You can create personalized packaging or limited-edition labels without slowing production. This flexibility helps you cater to different markets, enhance customer engagement, and strengthen brand loyalty.

10. Reduced Downtime with Quick Changeovers

Keep Your Line Running

Inline flexo machines allow fast plate changes, substrate swaps, and finishing adjustments. Reduced downtime means your production line stays active longer, maximizing output and return on investment. You spend less time waiting and more time producing high-quality labels and packaging.

Advantages Recap Table

| Benefit | Feature | Impact on Your Production |

|---|---|---|

| Print Quality | High-resolution inline printing | Premium labels & packaging |

| Efficiency | Multi-step integration | Faster throughput |

| Cost Savings | Less waste | Lower production costs |

| Flexibility | Supports multiple substrates | Versatile operations |

| Varnishing | Inline coatings | Enhanced packaging appeal |

| Food Compliance | Low-migration inks | Safe, regulatory-compliant packaging |

| Pharma Accuracy | Barcode & variable data | Compliance & traceability |

| Automation | Remote monitoring & controls | Less labor, fewer errors |

| Personalization | Variable data printing | Increased brand engagement |

| Downtime Reduction | Quick changeovers | Continuous production flow |

Conclusion

Investing in an inline flexo printing machine elevates your packaging and labeling operations, delivering unmatched precision, efficiency, and flexibility. Whether you need inline flexo printing for quality labels, food packaging inline flexo solutions, or pharmaceutical labels inline printing, these presses ensure consistent high-quality results, reduce costs, and boost productivity. Upgrade today and experience the advantages of an inline flexographic press firsthand.