In the competitive world of packaging, non-woven shopping bags and flour sacks represent a growing market driven by eco-conscious trends and food safety standards. Achieving vibrant, durable, and cost-effective printing on these materials, however, presents unique challenges. The porous nature of non-woven fabrics and the rigorous handling demands for flour bags require specialized printing solutions. This guide explores the optimal technologies to deliver high-quality graphics that enhance brand visibility and durability. At PuJi Machinery, we engineer printing presses that combine efficiency with exceptional print quality, offering tailored solutions for these versatile substrates. For businesses seeking to elevate their custom non-woven bag printing or produce high-speed flour bag packaging, selecting the right technology is the first step toward market leadership.

Table of Contents

ToggleUnderstanding the Printing Challenges for Non-Woven and Flour Bags

Non-woven polypropylene (PP) bags and multi-wall flour sacks are not standard printing substrates. Their textured, absorbent surfaces can lead to ink spreading, resulting in dull colors or blurred details. For flour bags, the added requirements of durability—resisting abrasion during transport and storage—mean the print must not only look good but also withstand physical stress. Furthermore, production often demands high speeds to meet volume orders cost-effectively. Therefore, the ideal printing solution must address three core challenges: ink adhesion and vibrancy, print durability, and high-volume production efficiency.

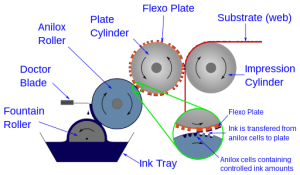

Flexographic Printing: The Leading Solution for Volume and Durability

Flexographic printing, particularly using Central Impression (CI) flexo presses, stands out as the premier choice for both non-woven and flour bag production. This method excels in high-speed, long-run scenarios, offering excellent ink coverage on porous surfaces. Modern flexo inks, including water-based and UV-curable options, bond effectively with non-woven fibers and paper surfaces, producing scratch-resistant prints. The quick-drying nature of these inks is crucial for maintaining speed and preventing smudging in stacked bags. For flour bags requiring high durability, flexo printing with robust ink systems ensures logos and information remain intact throughout the supply chain.

Comparative Analysis: Printing Technologies for Non-Woven and Flour Bags

| Feature | CI Flexo Printing | Digital Printing | Rotary Screen Printing |

|---|---|---|---|

| Best For | High-volume orders, durable bags | Short runs, customization | Very vibrant colors, simple designs |

| Print Speed | Very High (200-500+ m/min) | Low to Moderate | Moderate |

| Setup Cost & Time | Moderate setup time, plate cost | Low setup, no plates | High setup time, screen cost |

| Cost-Effectiveness (Long Runs) | Excellent (low cost per unit) | Poor (high cost per unit) | Good for very long runs |

| Color Vibrancy & Opacity | Excellent, high opacity achievable | Good, can struggle on dark fabrics | Superior, very thick ink layers |

| Design Flexibility | High (photopolymer plates) | Very High (variable data) | Low (limited detail) |

| Durability & Rub Resistance | Excellent with proper ink | Fair to Good | Excellent (thick ink film) |

Deep Analysis of Technology Advantages

CI Flexo Printing: The Volume Leader

CI Flexo is the backbone of industrial bag production. Its central drum design ensures perfect registration, allowing for precise multi-color printing even at high speeds. For non-woven bags, this means crisp logos and text; for flour bags, it ensures barcodes and nutritional information are scannably accurate. The real strength lies in its long-run economics. Once plates are made, the cost per bag plummets, making it unbeatable for orders of 50,000 units or more. Modern advancements, like gearless servo drives (featured in PuJi Machinery presses), further enhance efficiency by reducing waste and enabling faster job changeovers.

Digital Printing: The Customization Specialist

Digital printing shines in the growing market for personalized promotional bags or small-batch specialty flour packaging. It requires no physical plates, allowing for instant design changes and unique serialization. This is ideal for limited-edition runs or regional marketing campaigns. However, its slower speed and higher cost per print make it impractical for large-scale commodity production. Additionally, while inkjet technology has improved, achieving the same level of ink opacity and abrasion resistance as flexo on rough non-woven surfaces remains a challenge.

Rotary Screen Printing: The Color Impact Expert

Rotary screen printing deposits a thick layer of ink, resulting in exceptionally vibrant, tactile prints. This can be desirable for premium non-woven shopping bags where visual impact is paramount. However, the technology is less suited for fine details or complex photographic images. The high setup cost and time for engraving screens make it viable only for extraordinarily long, consistent runs. For flour bags requiring functional, durable prints rather than artistic designs, it is often an overinvestment.

Key Considerations for Choosing Your Solution

Selecting the best technology hinges on your order volume, design complexity, and durability requirements.

-

For large-scale manufacturers of standard non-woven shopping bags or commercial flour sacks, CI Flexo is the unequivocal choice. It delivers the necessary speed, durability, and lowest total cost of ownership.

-

For printers serving niche or promotional markets, a hybrid approach may be optimal: using flexo for base runs and digital for final personalization.

-

Ink selection is critical. For non-woven bags, UV-curable inks offer excellent rub resistance and color pop. For flour bags in direct contact with food, compliant water-based inks are essential for safety.

Why PuJi Machinery is Your Ideal Partner

At PuJi Machinery, we specialize in high-performance CI flexo presses engineered for substrates like non-woven fabrics and paper sacks. Our machines offer:

-

Precision Registration: Ensures sharp, consistent print quality batch after batch.

-

High-Speed Production: Maximizes output to meet large orders efficiently.

-

Durable Ink Systems: Compatible with a range of inks for superior adhesion and abrasion resistance.

-

Expert Support: From configuration to maintenance, we ensure your press operates at peak performance.

FAQ

Q: Can flexo printing achieve high-quality photographic images on non-woven bags?

A: Yes, with modern digital plate-making (HD flexo), CI presses can reproduce detailed images with excellent fidelity on non-woven materials.

Q: Is flexo printing environmentally friendly for non-woven “eco” bags?

A: Absolutely. Flexo can use water-based or UV inks with low VOCs, aligning with the sustainable ethos of reusable non-woven bags.

Q: What is the minimum economical order quantity for flexo printing on bags?

A: While variable, flexo typically becomes cost-advantageous for runs above 10,000-50,000 bags, depending on design complexity, due to plate costs.

Q: How durable is flexo print on a flour bag during shipping?

A: When paired with abrasion-resistant inks and proper curing, flexo prints on flour sacks are highly durable and withstand normal shipping and handling abrasion.

Q: Can one press handle both non-woven and multi-wall paper flour bags?

A: Yes. A versatile CI flexo press from PuJi Machinery can be configured with appropriate ink systems and tension controls to efficiently print on both substrates.

Conclusion

For non-woven shopping and flour bags, CI flexographic printing delivers the optimal balance of speed, quality, durability, and cost-effectiveness for high-volume production. By investing in the right flexo technology, manufacturers can meet rigorous market demands while enhancing brand appeal and operational efficiency.

Ready to optimize your bag production line? Explore PuJi Machinery‘s robust CI flexo solutions designed for superior performance on non-woven and paper substrates. Visit Our Web to discover how we can help you print your way to greater success.