In today’s competitive manufacturing and packaging landscape, efficiency, speed, and quality are the keys to profitability. One of the most transformative technologies driving this change is the inline printing machine.

Unlike traditional setups where printing and finishing are done separately, inline systems combine multiple stages—printing, coating, laminating, and cutting—into one continuous process. This integration helps manufacturers streamline production, reduce costs, and enhance overall print quality.

In this article, we’ll explore how inline printing machines benefit various sectors and reveal five industries that can significantly boost profits by adopting this technology.

Table of Contents

ToggleWhy Inline Printing Boosts Profits

Faster Production Speed

The biggest advantage of an inline printing machine is its ability to perform multiple functions—printing, varnishing, slitting, and finishing—in one pass. This reduces setup time and enables high-speed printing, making it ideal for large-scale production.

Reduced Labor and Operational Costs

By integrating processes, inline systems minimize manual intervention and handling. Businesses save on labor, reduce errors, and increase operational efficiency compared to separate packaging machines or offline flexo printing machines.

Better Quality Control and Less Waste

Inline systems maintain precise registration and color accuracy throughout the print run. With fewer material transfers, there’s less waste and better consistency—key factors in industries like food packaging and labeling.

Increased Flexibility for Short Runs and Customization

Modern industrial printing machines with inline capabilities can easily handle short-run, variable-data, and customized printing without halting production. This makes them perfect for today’s on-demand manufacturing environment.

Five Industries That Benefit Most from Inline Printing

Packaging Industry

The packaging industry relies heavily on speed, precision, and flexibility. Inline printing technology allows packaging manufacturers to print, laminate, and cut within a single system.

-

Applications: Food, beverage, and cosmetics packaging.

-

Advantages:

-

Faster turnaround for high-volume runs.

-

Improved print consistency and color matching.

-

Reduced lead time from print to shipment.

-

Perfect integration with packaging machines for seamless workflow.

-

Inline printing ensures brands can deliver attractive, durable packaging that enhances shelf appeal while keeping production costs under control.

Label Manufacturing

Label production demands precision and customization. Inline printing machines—especially advanced label printing machines—excel in this field by combining printing, varnishing, die-cutting, and rewinding in one operation.

-

Applications: Wine, beer, pharmaceuticals, and retail labels.

-

Advantages:

-

Shorter setup and changeover time.

-

Accurate registration and color alignment.

-

Support for variable data printing and barcodes.

-

Consistent output for small and large label batches.

-

For manufacturers aiming to meet increasing demand for personalized labels, inline technology offers scalability and quality at once.

Flexible Films & Pouches

Industries producing snack packs, pet food bags, or liquid pouches benefit immensely from inline systems.

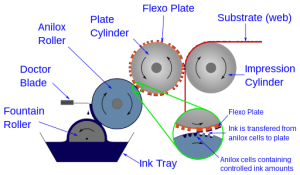

By integrating flexo printing machines with laminating and coating functions, businesses can enhance product durability and finish quality.

-

Applications: Flexible films, laminated foils, and resealable pouches.

-

Advantages:

-

Inline coating improves resistance and visual appeal.

-

Eliminates intermediate handling steps.

-

Reduces production bottlenecks.

-

Supports quick design adjustments for brand updates.

-

This is particularly valuable for food and FMCG companies that need consistent print quality across thousands of flexible packages.

Corrugated & Folding Cartons

The corrugated packaging and folding carton industries require precision and structural integrity.

Inline systems integrate printing and cutting with finishing features like creasing and die-cutting, reducing reliance on separate finishing stages.

-

Applications: E-commerce packaging, retail cartons, and display boxes.

-

Advantages:

-

Improved print-to-cut accuracy.

-

Reduced material handling and labor costs.

-

Faster delivery timelines.

-

Integration with industrial printing machines for automated finishing.

-

This efficiency enables packaging converters to meet large retail demands while maintaining consistent print quality.

Promotional & Specialty Printing

For premium or creative products, such as gift boxes, luxury packaging, or point-of-sale displays, inline systems provide the perfect combination of creativity and speed.

-

Applications: High-end packaging, promotional displays, and limited-edition boxes.

-

Advantages:

-

Inline UV coating, foil stamping, and embossing.

-

Enhanced product appeal and tactile finishes.

-

Reduced setup between creative print stages.

-

Better competitiveness in niche markets.

-

An inline printing machine with multi-finishing modules empowers brands to innovate without increasing costs or lead times.

How Businesses Can Maximize ROI

To fully leverage inline technology and improve profitability, companies should focus on strategic implementation.

Analyze Production Needs and Volume

Evaluate your production goals—high-speed packaging or short-run custom jobs—to choose the right configuration of inline printing machines.

Choose Inline Machines with Suitable Speed and Finishing Capabilities

Select systems compatible with your product materials and desired finishes—lamination, coating, or embossing—to ensure long-term versatility.

Optimize Workflow to Reduce Waste and Downtime

Integrate your inline system with existing packaging machines and industrial printing machines to streamline material flow and minimize waste.

Leverage Inline Capabilities for Premium and Customized Products

Use inline finishing features like metallic inks, UV coatings, or variable-data printing to deliver high-value, branded products that attract more customers and improve margins.

Conclusion

The rise of inline printing machines marks a major shift in how modern printing and packaging companies operate.

From label manufacturing to flexible packaging, corrugated cartons, and specialty printing, inline systems deliver measurable benefits—faster production, consistent quality, and reduced operational costs.

Whether you’re upgrading a flexo printing machine, integrating a label printing machine, or optimizing your packaging machine line, adopting inline technology can help you stay ahead of competitors and maximize your return on investment. Contact our specialists to discover how inline or flexo printing machine can boost your productivity and profits.